In the world of bowhunting, choosing the right broadhead can be the difference between success and disappointment. Among the myriad of options available, Grave Digger broadheads have garnered considerable attention for their innovative design and performance capabilities. This article undertakes a comprehensive review of Grave Digger broadheads, focusing on their precision, performance metrics, and the innovations and challenges present in their design. By delving into these aspects, hunters can make informed decisions when selecting a broadhead that aligns with their specific needs and preferences.

Evaluating the Precision: Grave Digger Broadheads

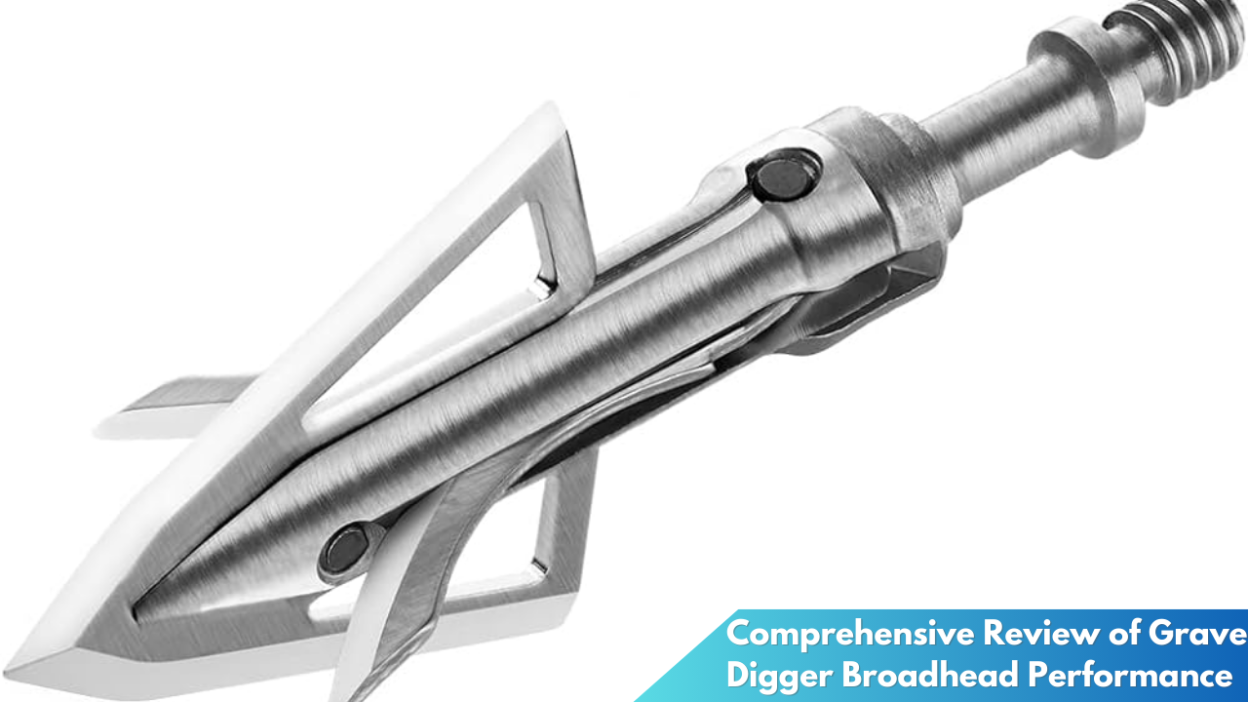

Precision is a paramount factor when evaluating broadheads, as it directly impacts the accuracy and effectiveness of a hunting shot. Grave Digger broadheads are renowned for their hybrid design, combining the cutting power of fixed blades with the accuracy of mechanical blades. This unique configuration is intended to enhance flight stability and precision, ensuring that arrows hit their intended target consistently. Hunters have reported that Grave Digger broadheads exhibit remarkable precision even at extended ranges, making them a popular choice for those seeking reliable performance in various hunting scenarios.

A key element contributing to the precision of Grave Digger broadheads is their aerodynamic profile. The sleek design minimizes drag during flight, allowing for a true and steady trajectory. The combination of a small fixed blade for initial penetration and mechanical blades that deploy upon impact is engineered to maintain a straight flight path while maximizing cutting efficiency. Additionally, Grave Digger broadheads are known for their ease of tuning, allowing hunters to achieve optimal alignment with their arrows and bows, further enhancing precision.

Field tests by experienced hunters have consistently demonstrated the reliability of Grave Digger broadheads in terms of precision. Reports suggest that these broadheads perform exceptionally well in diverse environmental conditions, including wind and rain, which can often pose challenges for less aerodynamically efficient designs. This reliability in maintaining precision across different conditions is a testament to the advanced engineering behind Grave Digger broadheads.

Performance Metrics and Field Test Results

Performance metrics are crucial in evaluating the effectiveness of broadheads, encompassing factors such as penetration, cutting diameter, and durability. Grave Digger broadheads have consistently scored high in these metrics due to their innovative design. The hybrid mechanism allows for deep penetration, as the fixed blade initiates entry, and the mechanical blades expand to create large wound channels, increasing the chances of quick, humane kills.

Field tests have shown that Grave Digger broadheads maintain their structural integrity even when used on large game animals. The durability of the blades, crafted from robust materials, ensures that they remain sharp and effective after multiple uses. Hunters have noted that the broadheads offer consistent performance, maintaining their quality and effectiveness over repeated hunts, which is a significant advantage for those who hunt frequently.

Real-world hunting scenarios reveal that Grave Digger broadheads excel in terms of cutting diameter, with mechanical blades extending significantly upon impact. This feature is particularly beneficial for hunters aiming for maximum damage and rapid blood trails. The broadheads’ ability to deliver substantial wound channels contributes to efficient game recovery, a critical aspect for ethical hunting practices. Overall, the performance metrics and field test results illustrate that Grave Digger broadheads are a reliable choice for discerning hunters.

Innovations and Challenges in Broadhead Design

Grave Digger broadheads embody several innovations that set them apart in the competitive market of hunting equipment. One of the most notable innovations is their hybrid design, combining the strengths of both fixed and mechanical blades. This integration addresses the traditional trade-offs between penetration power and accuracy, offering a solution that maximizes both. The expandable blades are designed to deploy smoothly upon impact without compromising the flight path, showcasing the advanced engineering involved in their creation.

However, with innovation come challenges. The hybrid design of Grave Digger broadheads, while advantageous, requires precise manufacturing standards to ensure reliability. Any deviation in production could potentially affect the deployment of the mechanical blades, impacting their performance. Quality control is thus a critical aspect of their production process to maintain the high standards expected by hunters.

Another challenge lies in market differentiation. As more hybrid broadheads enter the market, maintaining a competitive edge becomes increasingly difficult. Grave Digger broadheads must continue to innovate and address any emerging issues to sustain their reputation among hunters. The ongoing development and refinement of their designs are imperative to meet the evolving demands of the hunting community and to overcome the challenges inherent in broadhead manufacturing.

In conclusion, Grave Digger broadheads demonstrate a remarkable blend of precision, performance, and innovative design. Their hybrid configuration offers hunters the advantages of both fixed and mechanical blades, resulting in a broadhead that excels in precision and impact while maintaining durability in the field. Despite the challenges associated with their production and market competition, Grave Digger broadheads remain a preferred choice for hunters seeking reliability and efficiency. As the world of broadhead design continues to evolve, the commitment to innovation and quality will be crucial for Grave Digger broadheads to maintain their place as leaders in the industry.